Bauman drop spreaders prevent waste and property damage with the most accurate de-icing dispensing equipment on the market.

Backed by a tradition of quality for over 40 years and with 9 models to choose from, Bauman has the right solution for you.

Model 220 Features

The 220 Push sander is light weight and easy to maneuver.

Construction

Utilizing 12 gauge steel and a durable powder coat finish, the 220 model is built to last.

Construction

Utilizing 12 gauge steel and a durable powder coat finish, the 220 model is built to last.

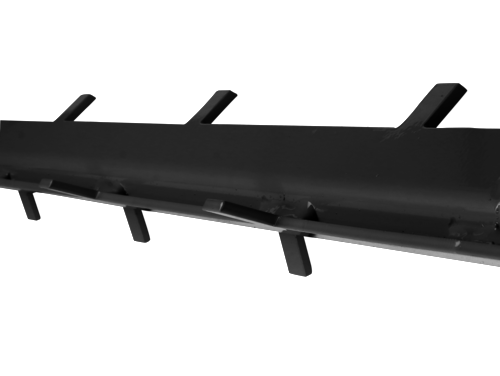

Finger Bar

A unique polymer finger bar has a flexible memory in cold weather and retains its shape. The bar defines pressure and helps release an even quantity of de-icing material as seen with the cross hatch pattern when material is dropped.

Agitator Bar

The agitator bar rotates in the hopper to help keep salt and sand from bridging or clumping. The bar ensures the material passes through to the drum and then to the ground for an even application.

Salt / Sand Drum

The rotating distributor drums spread de-icing material in an even and consistent cross hatch pattern. De-icing material can then "creep" and spread out which results in an efficient use of material.

Spread Pattern

The rotating distributor drums spread de-icing material in an even and consistent cross hatch pattern. De-icing material can then "creep" and spread out which results in an efficient use of material.

Tension Lever Assembly

The assembly regulates the rate of flow for different types of material (i.e.: fine sand vs coarse salt). The lever allows for fine tuning the rate of flow of material.

Sealed Bearings

Sealed bearings protect against environmental wear. They are also easily maintained and re-greasable.

Direct Gear to Gear Drive

The gear is simple to use and easy to maintain.

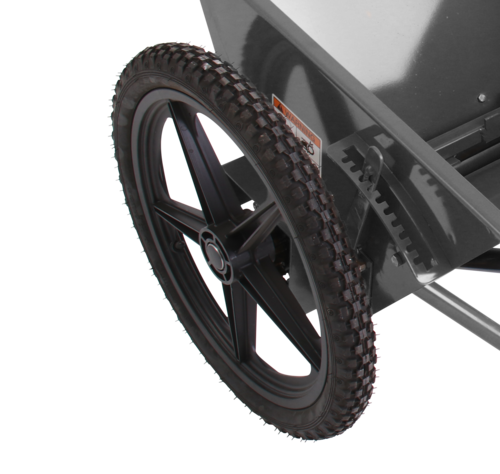

Pneumatic Snow Tire

The tire delivers good traction on snow and ice.

Covers

Optional soft cover available